Top Ten Challenges For Solid-State Lighting: #8 – “Glare”

March 2015 - by Aurelien David, SORAA's Chief Scientist

I like this

In the last series, I discussed the need for higher-brightness LEDs. This may sound surprising to those who complain that LEDs are already “too bright” – by which they usually mean that they have excessive glare.

Glare is a general term describing an excessively harsh light to the point of discomfort or disability. The definition may be loose but the problem is real – and it is true that LEDs don’t have a great track record here, with some of the worst offenders found in streetlights and in directional lighting. In both cases, the cause is simple: these applications require a lot of light to be directed in a controlled direction and as little light as possible spilling outside of this direction. Achieving far-field patterns with such sharp variations can be a challenge for optical designers, especially when price considerations restrict them to simplistic optical designs.

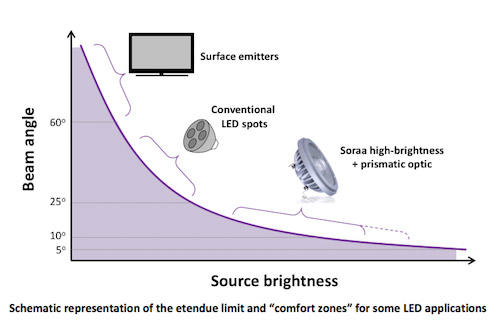

Why this state of affairs? Glare has been the topic of many studies, and various formulas relate it well enough to the luminance and illuminance of light sources; however, these are not simple to use as they depend critically on the actual luminaire layout. In some environments like office lighting, layouts are fairly standardized and the existence of strict guidelines (e.g. IES RP-1, DesignLights Consortium) means that glare is mostly under control. In contrast, there are no simple metrics and no specifications in cases such as street lighting and general directional fixtures. The incentive to get glare under control is therefore limited and, as often, lumens come first (for instance, to claim that a retrofit system is “equivalent” to a given wattage of filament lamp). No doubt, these instances lead to the perception that LEDs suffer from their excessive brightness. Why then would we bother pushing the envelope on brightness? Because in reality more brightness enables less glare.

How so? Starting from a very bright light source, it is easy enough to design an optic which will direct most of the light in the beam and very little in the spill – essentially making the light source invisible outside the beam. A spectacular example of this concept is the traditional AR111, whose very bright filament enables a narrow beam angle while at the same time completely hiding the filament at glancing angles. The trouble starts when manufacturers try to employ LEDs of average brightness for narrow-beams and get too close to the etendue limit – spill light then become hard to avoid and leads to glare.

In the short term, this suggests a conservative philosophy: for a given LED technology, manufacturers should understand what beam angles can reasonably be achieved with low-glare and stick to this ‘comfort zone’. Subsequent improvements in brightness will enable narrower and cleaner beams and get us closer to an ideal, invisible light source. In the longer run, we can expect more disruptive progress with the proliferation of dynamic/smart beam control – a taste of which we are just about to get with the laser-based headlights announced by high-end auto manufacturers.